Palletizer: Skillfully palletized. Perfectly transported.

Enormous design capability combines special competences from steel and mechanical engineering with intelligent control technology. With a large number of parallel running movements the palletizers create homogeneous, sensitive flows to handle the packaged goods precisely even at maximum capacity and not unnecessarily stress them.

High-performance palletizers for optimal transport

The Möllers Packaging Technology is a dependable and competent contact when it comes to palletizers, wrapping systems and secure handling of products on their transport route from A to B. The employment of palletizing systems demands a high degree of flexibility from efficient formation of stable layers of wrapped goods. Optimal load security has uppermost priority for the provision of services to customers.

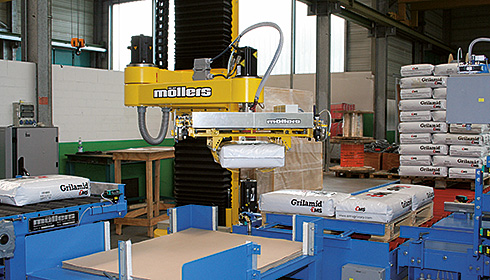

Automatic palletizing at the highest level

Enormous design capabilities combine special competences from steel- and mechanical engineering with intelligent control technology: With a multitude of parallel movements, the palletizers create homogeneous, sensitive processes to handle packed goods precisely during palletizing and not unnecessarily stress them. These are for example palletizing robots which equip a pallet with layers of the respective products by means of a software-controlled gripper arm system and a gentle mode of operation. The robot also has grippers to provide the service the customer requires.

Palletizing systems for all industries

The company, with its headquarters in Germany, has for over 65 years as a manufacturer of high-quality palletizing solutions been well-known worldwide for its unrivalled robustness, reliability and maximum performance. The systems employed meet the requirements of almost all sectors and industries. Within a few seconds, the palletizing systems ensure stable and even stacking of products.

Optimum palletizing thanks to effective palletizing technology

Fully-automatic palletizing systems offer companies maximum flexibility and can be switched to different product formats and pallets. This seamlessly integrates systems into automated workflows. The machines function in an energy-saving manner, with low noise and fulfil their task with high availability. An example of this is the articulated-arm robot which impresses with its flexible adaptation to the conditions in the palletizing of products in industry. When the robot comes into contact with the packed goods, corresponding gripper devices such as a bag- or suction gripper ensure gentle handling.

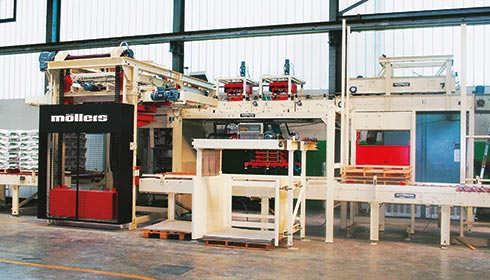

Core competence layer-palletizer

Palletizers for layers guarantee maximum secure transport through the formation of stable shipping units and thus ensure highest resistance to stress in global freight transport.

The layer palletizer of the series PLS-C create a maximum capacity of 3000 bags/hour and thus fulfil the prevailing requirements in different industrial sectors such as fertilizers, chemicals or petrochemicals.

Advantages of our palletizing systems

-

gentle packed-material handling method

-

tailor-made solutions

-

high load security thanks to effective load stabilization

-

wide selection of palletizing systems and gripper devices