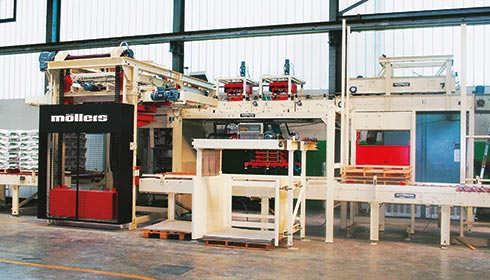

Layer palletizer: Perfect layer palletizing

The Möllers Packaging Technology range comprises several standard model ranges. PLS-Automatic palletizers address the tasks of the chemical and petrochemical industry in the form of model series C, with nominal capacities of 1500 to 3000 bags per hour.

Enormous design capability unites special competences from the steel- and machine-building sector with intelligent control technology: The PLS-C is a specialist in the chemical and petrochemical industry, the fertilizer industry as well as food industry bulk materials. With a number of parallel operating movements, it achieves homogeneous, gentle flows in order to handle packed goods precisely at maximum capacity and not to stress them unnecessarily.

The Möllers Packaging Technology high-capacity palletizing systems have been known for their unrivalled robustness, reliability and high performance for over 65 years.

How our layer palletizers work

Mechanics and automation

Top league automatic palletizers efficiently fulfill a wide range of needs for all kinds of packed goods’ characteristics and operational conditions. They are adaptable to various packed goods and pallet formats and can be seamlessly integrated into automatic workflows. They work in an energy-saving manner, with low noise levels and fulfill their task with the greatest availability levels. This high mechanical demand is combined with highly-automated controls whilst giving absolute reliability.

The Möllers Packaging Technology range comprises several standard model ranges. PLS-Automatic palletizers address the tasks of the chemical and petrochemical industry in the form of model series C, with nominal capacities of 1500 to 3000 bags per hour.

Proven packaging solutions

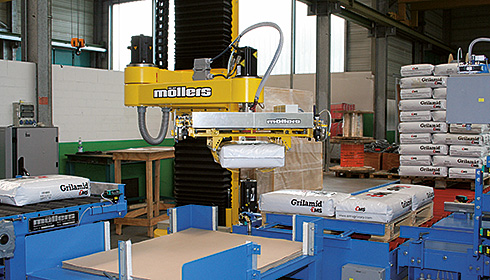

Whether highly sensitive, solid, poudery or granular bulk materials: We convey and palletize bagged goods of all kinds with the due care that matches their special character. Specialized in bagged goods susceptible to deformation, Möllers Packaging Technology palletizers are characterized by their extremely gentle mode of operation and their suitability for all kinds of bagged goods.

Our goal: precisely formed, stable pallet loads for secure onward transport which, even during high-capacity production, avoid puncturing, tearing, bulging or bag breakage.

Perfect layer palletizing

The four-sided layer forming, the divided slide plate, the low depositing height and the upper pressure plate determine the perfect stack during layer palletizing. When the divided slide plate opens, the homogeneous flow function is continued with minimal movement while the layer pressure plate presses gently from above, layer by layer. Special feature: Thanks to aerated slide plates, bag layers are positioned perfectly – the friction coefficient is lowered. Möllers Packaging Technology fulfills local conditions such as humidity and temperature variations – and guarantees consistently high stacking quality.

How does layer palletization work?

Competencies

-

Great adaptability to special material characteristics

-

Individual composition through modular design

-

Suitability for most varied bag- and pallet formats

-

Extremely gentle material handling method

-

Effective load stabilisation with film insert und antislip-glueing

-

Low noise-level