PLS-B: gentle bag-guiding at maximum speed

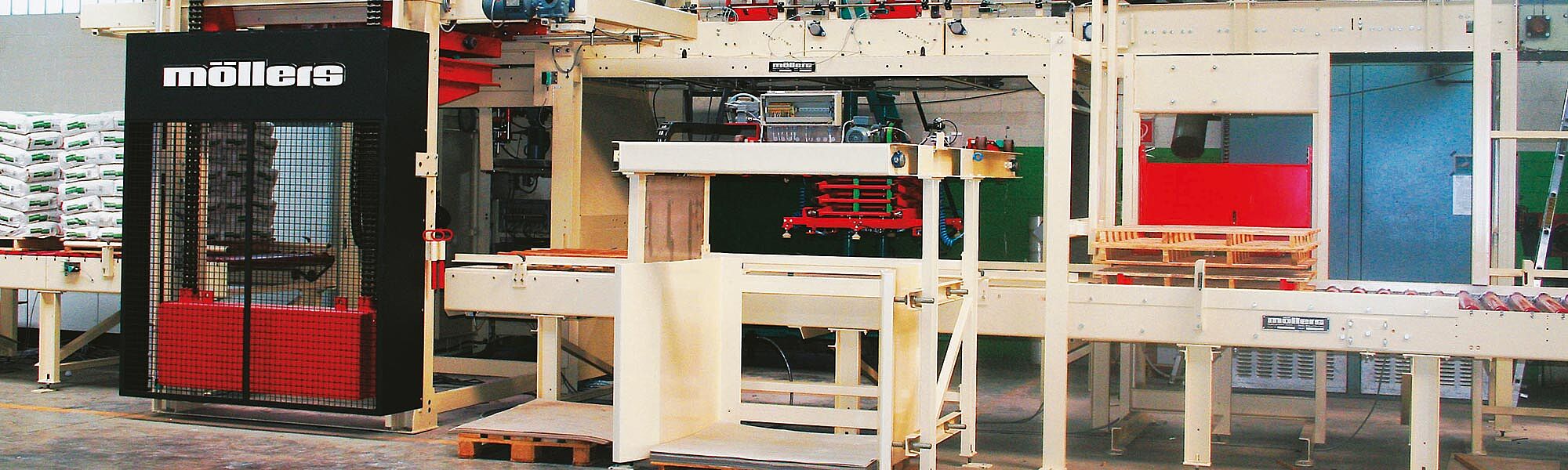

High-speed palletizers from the Möllers Packaging Technology meet the demands of the building materials industry with special equipment options and greatest availability.

Special building materials: gentle transfer of bag layers

Perfectly adapted to the enormous challenges of the building materials industry, high-performance palletizers of the PLS-B series prove their worth; with throughput rates of 1200 to a maximum of 3000, 4000 and 5000 bags / hour, depending on the layer pattern employed.

Often used are kraft paper valve bags which, in filled state, retain their shape relatively well - accordingly, the palletizer B-series are equipped with turning flaps to turn the bags in the transverse position. They inhibit the approaching bag on the conveyor belt, off-center, the resulting torque leads to the 90° rotation.

Gentle sack guidance

Bags of all common sizes and weights are palletized in a pack pattern of four to ten. The high-performance palletizers of the PLS-B series are equipped with timing belts. The use of an installed dual lower guide for gentle transfer of the bag layers on to the slide plate not only serves to secure the large palletizing capacity, it also protects the bags.

Technical details

Technical data

- Standard palletizing capacity: 700 to 4500

- Packs / hour depending on model and layer pattern (higher capacity on request)

- Typical pallet formats: 800 x 1200mm, 1000 x 1200mm

- Typical palletizing formats (bags): 450 x 300mm

Technical images

Kernkompetenz Lagenpalettierung

Four-sided layer formation:

The layer is brought into position by the layer infeeder, then aligned to the desired format aided by the dual-side layer forming device and is positioned exactly over the pallet.

Neat stack image:

The layer is positioned symmetrically on the pallet by drawing over the slide plate on both sides.

Upper pressure plate:

The upper layer pressure plate equalizes each individual layer and levels out possible deformations – the goal is a neat, compact stack image. The layer pressure plate thereby equalizes each layer at a stack - with consistent pressure.