Motor building materials industry

Beckum, headquarters of the Möllers Packaging Technology, was shaped by the cement industry. Since 1952 the Möllers Packaging Technology has been building upon the Full Line. High Quality. Traditonally customers feature market leaders in the bulk material manufacturing and bulk material processing industrial sectors.

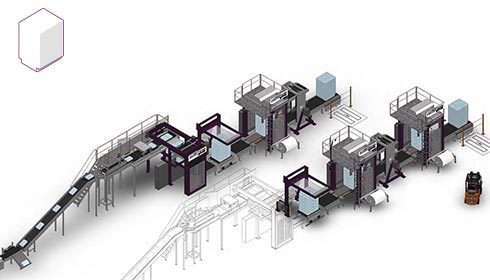

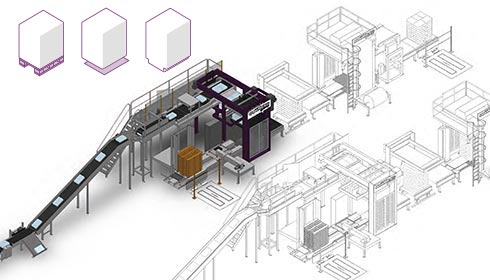

From bulk material to general cargo

Whether raw, intermediate or finished products: The required materials of the building sector need to be stored, dosed, weighed, transported and securely wrapped. For almost every combination option "product, container, weight" the Möllers Packaging Technology finds a cost-saving, high performance filling solution – depending on which challenges the building materials with their different material characteristics or bulk densities pose.

Palletizer for the Building Materials Industry

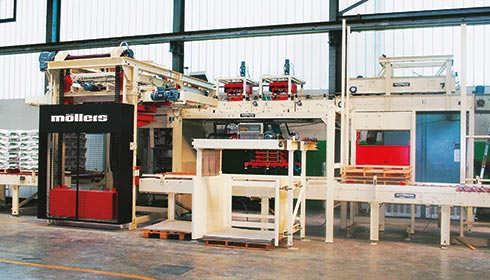

Layer palletizer for the Building Materials-Industry (PLS-B)

Bags of all usual formats and weights are palletized – according to layer pattern with up to 5000 bags/hour.

Low level palletizer PFS: attractive for special tasks

The slide plate of the low level palletizer PFS functions at floor level – for palletizing with frequent product change and capacities up to 1200 bags/hr.

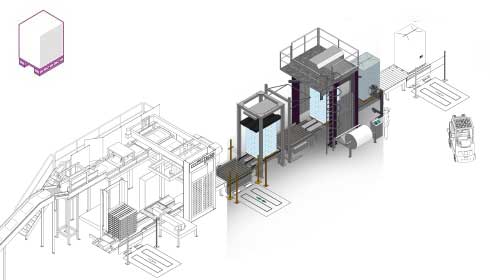

PHS: Palletizing and stretch hooding in one machine

The PHS combines as 2in1 in one machine the low level modular palletizer with an automatic stretch hooding machine.

In a confined space scenario: the ROMEO® Palletizing robot

A palletizing robot is a palletizing all-rounder – the ROMEO® demonstrates its high-precision capabilities in confined spaces in particular.

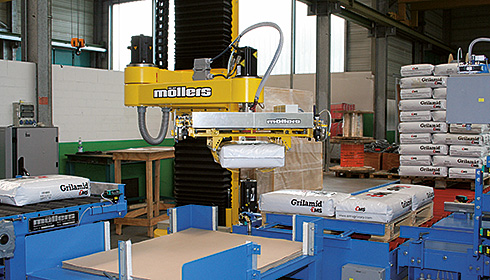

Articulated robot with gripper systems

Designed for high-performance and precise placing: the articulated-arm robot with individually developed gripper.

Wrapping machines for the Building Materials Industry

Automatic stretch hood machine (HSA-Vario)

Our stretch hood machine utilizes the restoring forces of the film in order to bond pallet and load tightly and securely with each other.

HSA-Vario D

Wrapping machine with two bobbins and patented film-end ejector

Award won: palletless shipping units (PSH-1 and PSH-2)

Palletless packsare shipping unit, transport security and weather protection in one. Available: 2- or 4-Way shipping units

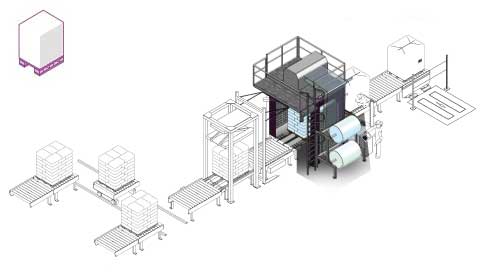

PSH-Vario: one system, three options

As a pioneer, the Möllers Packaging Technology supplies a universally functioning system which - at the touch of a button and at maximum speed - wraps packs with pallet, with slip-sheet as well as without pallet.

PHS: Palletizing and stretch hooding in one machine

The PHS combines as 2in1 in one machine the low level modular palletizer with an automatic stretch hooding machine.

Shrink film technology with film shrink frame (FSA)

Where goods have hardly any intrinsic stability, the FSA tubular film covering machines with separate shrink frames are recommended.

Wrap stretch-film technology: Favorably-priced load security

For lines with low capacity requirements product pallets are secrured by favorably-priced wrap stretch systems.